Introduction:

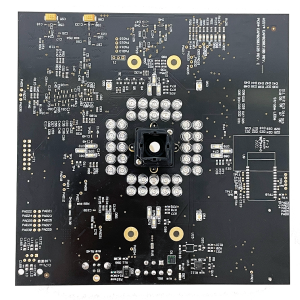

In the ever-evolving automotive industry, precise wheel alignment is a critical aspect of optimizing vehicle performance and ensuring driving safety. Behind the scenes of modern wheel aligners lies a crucial component: PCBA (Printed Circuit Board Assembly) and PCB (Printed Circuit Board) technology. In this article, we delve into the significance of PCBA and PCB Assembly in wheel aligners and their impact on ac curate alignment, vehicle performance, and overall driving experience.

curate alignment, vehicle performance, and overall driving experience.

Accurate Alignment for Optimal Performance:

Proper wheel alignment plays a pivotal role in maximizing vehicle performance. With the integration of PCBA and PCB Assembly in wheel aligners, automotive technicians gain access to precise measurements and adjustments. This advanced technology allows for accurate alignment of the wheels, including essential parameters such as camber, caster, and toe angles. By achieving the manufacturer’s specified alignment, wheel aligners equipped with PCBA and PCB Assembly enable improved steering responsiveness, enhanced tire longevity, increased fuel efficiency, and even tire wear.

The Role of PCBA and PCB Assembly:

PCBA and PCB Assembly act as the backbone of wheel aligners, serving as the electronic control system responsible for capturing and analyzing wheel data. Through a network of sensors and sophisticated algorithms, the PCBA interprets the signals received from the wheels, providing real-time feedback to technicians. This allows for precise adjustments to be made to suspension components, ensuring accurate alignment and optimal vehicle performance.

Advantages of Cutting-Edge Technology:

The integration of cutting-edge PCBA and PCB Assembly technology in wheel aligners offers a multitude of benefits. The high-speed processing capabilities of modern PCBs enable faster data analysis, reducing alignment time and increasing overall productivity. Additionally, the use of advanced electronic components enhances the reliability and durability of wheel aligners, providing automotive professionals with a robust and dependable alignment system.

Driving Safety and Customer Satisfaction:

Accurate wheel alignment not only optimizes vehicle performance but also significantly contributes to driving safety. Proper alignment ensures stable handling, reduces the risk of tire blowouts, and improves overall vehicle stability. By utilizing PCBA and PCB Assembly in wheel aligners, automotive technicians can deliver precise alignments that enhance driving safety, customer satisfaction, and ultimately, the reputation of their service centers.

Conclusion:

PCBA and PCB Assembly technology have revolutionized the wheel alignment process, offering accurate measurements, precise adjustments, and enhanced vehicle performance. The integration of these advanced electronic components in wheel aligners ensures optimal alignment, driving safety, and customer satisfaction. By utilizing cutting-edge PCBA and PCB Assembly technology, automotive professionals can take wheel alignment to new levels, providing their customers with improved handling, increased tire longevity, and a safer driving experience.